Misano products

MISANO Group has concluded an agreement for the production and commercialization under its own brand of innovative products with a strong orientation towards reducing environmental impact and for the protection of the health of workers of its traditional clients (steelworks), which complement the range of current products:

- TA-POM (pumice-based powder for the covering of ingot molds for casting

- WEDS™ (prevention of oxidation of chrome in slag)

The “Volcanics” are products derived from volcanic minerals that have been studied and developed by the MISANO Research and Development (R&D) Team starting from 2020, which led in 2023 to the definition of two solutions with a high ecological impact for the steel industry.

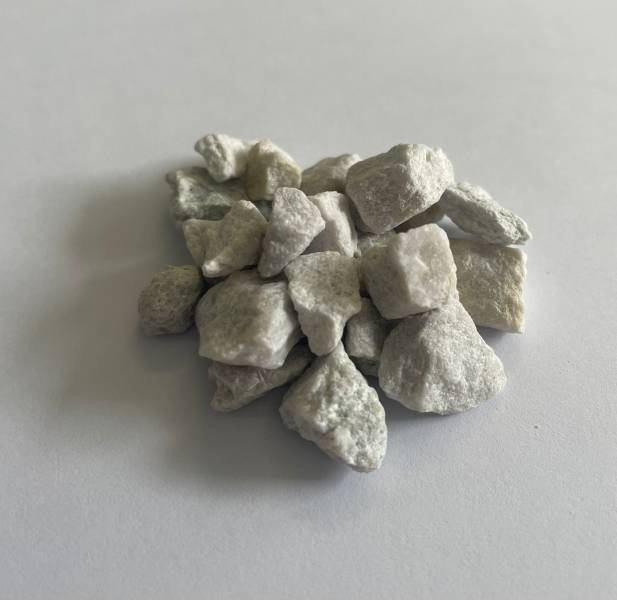

Pumice is a naturally expanded alveolar magmatic mineral. Being a natural volcanic inert, it is ecological. The innovative project consists of using the new TA-POM product (based on pumice) as an insulating powder in the production of ingots or castings, as an alternative to rice hull ash. Rice hull ash is a byproduct of the combustion in the rice processing procedure, a lightweight product with excellent insulating characteristics but not healthy (contains crystalline silica).

With Legislative Decree June 1, 2020, no. 44, respirable crystalline silica dust and work entailing exposure to respirable crystalline silica dust generated by a processing procedure, are included in the list of Processes and Agents involving a risk of carcinogenic exposure.

TA-POM has the following advantages:

- 100% natural of quarry origin

- Does not dirty the casting area and does not create problems with accidental inhalation

- Equivalent, even better, thermal insulation compared to rice hull ash

- Patent covered application

It is a product mixture of minerals.

It is used as the main flux in electric arc and induction furnaces for the production of high-Chromium steel and serves to prevent the oxidation of Chromium from the scrap charge, achieving Chromium recovery from the scrap equivalent to 95-98% yield.

Therefore, it results in less generation of melting scraps in general and especially for Chromium, with positive impacts both on disposal costs and, above all, significantly decreasing the amounts that are released into disposal cycles with a marked reduction of the environmental impact.

Applications of the WEDS™ lines

Stainless steel in melting processes with electric arc or induction furnaces.

Main advantages of the WEDS™ lines

- Optimizes ferrochrome yield, achieving 95-98%.

- Reduces Cr2O3 content in slag to

- Minimizes the risk of hexavalent chromium as waste.

- Promotes foamy slag formation in the electric furnace.

- Accelerates the melting process, reducing "power on" time